Green Hydrogen Production Revolution

We transform the industry with our advanced alkaline technology providing the lowest cost and highest efficiency - more than any other technology. We have updated water electrolysis and made the RIGHT WAY to do it

Revolutionary Technology Driving Change

Renewable Integration

Control Innovations

Electrolysis Advancements

Our cutting-edge electrolysis technology ensures efficient and cost-effective hydrogen production.

Advanced electronics enhance efficiency and stability with automatic control systems.

Combining green hydrogen production with renewable energy sources perfectly for a cleaner and sustainable process, with no delays.

Alkaline Electrolysis Explained

Chemical Process

Chemical decomposition produced by passing an electric current through a solution containing ions.

Material Innovation

Uses synthetic membrane, stainless steel, and low alkaline concentration of KOH.

Validated Success

Technology has undergone industrial testing with attractive NPV, EBIT, and IRR projections.

Revolutionary Alkaline Technology

Electrolysis and Control Innovation

We have developed advanced electronic to enhance the efficiency and stability of hydrogen production.

Electrolysis Advancements

Our cutting-edge electrolysis technology ensures efficient and cost-effective hydrogen production.

Renewable Energy Integration

We combine a perfectly matched solution for green hydrogen production with variable sources for a more sustainable process.

- We only need 38 kWh/kg H2

- Our innovative design enables optimal electrical range operation, ensuring superior perfonmance and energy savings.

- We use synthetic membrane, and stainless steel.

- Low alkaline concentration (KOH)

- Impressive efficiency, outperforming the industry standards

Hydrogen Market Applications

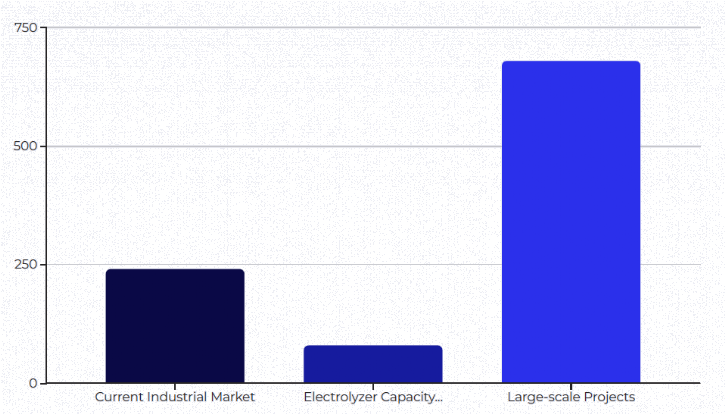

Market Opportunity

- Less than 5% of H2 comes from electrolysis due to high production costs from low electrical efficiency (averaging 60%). Our technology addresses this gap in a market growing at 5% annually.

- Demand for electrolyzer capacity of 80 GW until 2030 Source: IEA

- Industrial market evaluated in 240 billion euros in 2023, growth 5% Source: MarketsAndMarkets

- More than 680 large-scale hydrogen projects have been announced globally Source: McKinsey

- Global demand growth 5% Source:IEA

- Hydrogen production methods 99% produced from fossil fuels through SMR and cracking Source: IEA

Technology Comparison

Our Advanced Alkaline Technology

Highest efficiency, lowest cost

Standard Electrolysis

60% average efficiency

Fossil Fuel Methods (SMR)

99% of current production

Join Us, in shaping the clean and sustainable energy of today and the future!